Surface-set diamond bits are engineered to deliver reliable performance in medium-hard to hard, abrasive, and competent formations. This article talks about the technology behind surface-set diamond bits and how ROCKCODE produces premium bits and extensive experience to deliver reliable and cost-effective drilling solutions.

What are Surface-set Diamond Bits

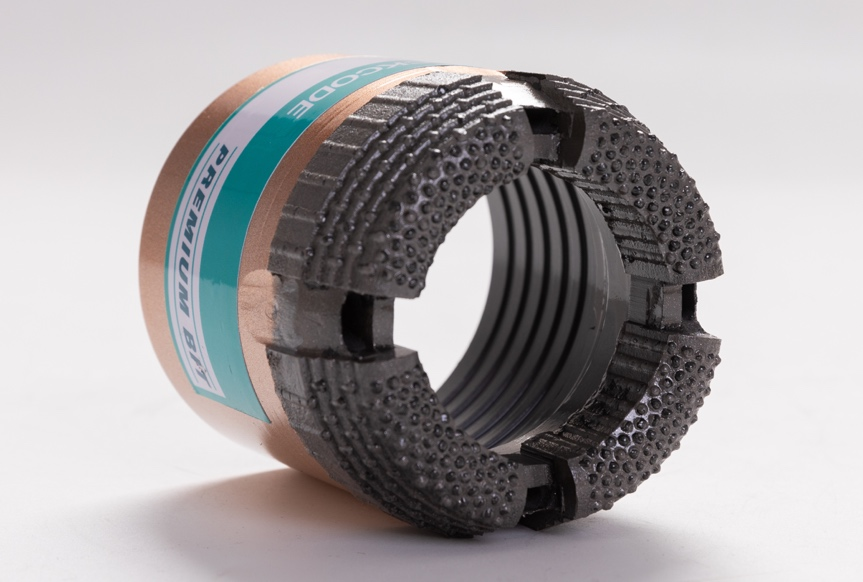

Surface-set diamond bits incorporate a single layer of large, carefully selected natural diamonds, each individually handset into a durable metal matrix, typically composed primarily of tungsten carbide. In this design, the exposed diamonds perform the cutting action directly against the formation. The result is a sharp and aggressive cutting behavior, well-suited for achieving high penetration rates in hard and consolidated rock formations.

Unlike impregnated diamond bits,where fine synthetic diamonds are uniformly distributed throughout the matrix and are gradually exposed as the matrix wears ,surface-set bits rely solely on the outer layer of exposed natural diamonds for cutting. Once these diamonds are worn down, the bit can either be re-set with new diamonds or replaced, depending on its wear condition and operational requirements.

The ROCKCODE Advantages

ROCKCODE's commitment to excellence is evident in every surface-set diamond bit we produce.

1. Premium Raw Materials

The performance of a surface-set diamond bit depends largely on the quality of its surface-set diamonds and the matrix’s capacity to securely hold them, as well as its inherent hardness and resistance to wear. ROCKCODE sources its tungsten powders and natural diamonds from global leaders in material supply. Our standard range of natural diamonds for surface-set bits is chosen in a special all-round grade known for its exceptional quality. These stones are selected for their high impact resistance, making them a versatile and reliable choice for a wide array of drilling conditions. The hard-wearing matrix ensures that the diamonds are held firmly in place, providing consistent cutting power.

2. Rich Manufacturing Experience

With over a decade of manufacturing experience and insights drawn from extensive geological exploration data, ROCKCODE continuously refines its formulations and processes, delivering well-engineered designs backed by proven field performance. For instance, our surface-set bits are manufactured using a hard matrix with high resistance to erosion. This deliberate design ensures strong diamond retention, providing effective protection and extending the overall service life of the bit. Furthermore, enhanced production efficiency streamlines our manufacturing, allowing us to provide these high-quality bits with greater cost-effectiveness, delivering outstanding value to our clients.

3. Custom Design Capability

We recognize that every drilling project presents unique challenges. Therefore, ROCKCODE's technical team possesses the expertise to independently design and customize both core and non-core bits to meet specific geological formations and client requirements. To obtain optimal drilling performance, ROCKCODE surface-set bits are available in various crown profiles. As illustrated in our product catalog, our standard profiles include:

Multi-step and semi-round profiles for enhanced stability and efficiency.

Face discharge bits for improved cuttings removal and cooling.

Non-coring bits with a concave profile and specialized slotted face discharge double dimple surface-set bits for specific application needs.

4. Technical Consultation

ROCKCODE is delighted to provide professional advice on bit selection, application, and drilling optimization. Our team is ready to share its expertise to help you improve operational efficiency and reduce overall costs, ensuring you have the right tool for the job. We also provided field support when you needed.

→ For more information about ROCKCODE’s Surface-Set Diamond Bits, please visit: https://www.rockcodebit.com/surface-set-diamond-core-bit.html

→ Email us at: [email protected]

→ Information in this article is for general reference only. For specific drilling projects and drilling bits, please consult qualified professionals. Thank you.