In modern pharmaceutical and industrial production, precision, efficiency, and reliability are critical factors in packaging operations. Among the most effective solutions for high-speed, accurate labeling is the SANTUO's vial labeling machine with turntable. Designed for small bottles, vials, ampoules, and oral liquid containers, this machine combines innovative mechanical design with advanced automation technology to ensure precise and consistent labeling across high-volume production lines.

What Is a Vial Labeling Machine with Turntable?

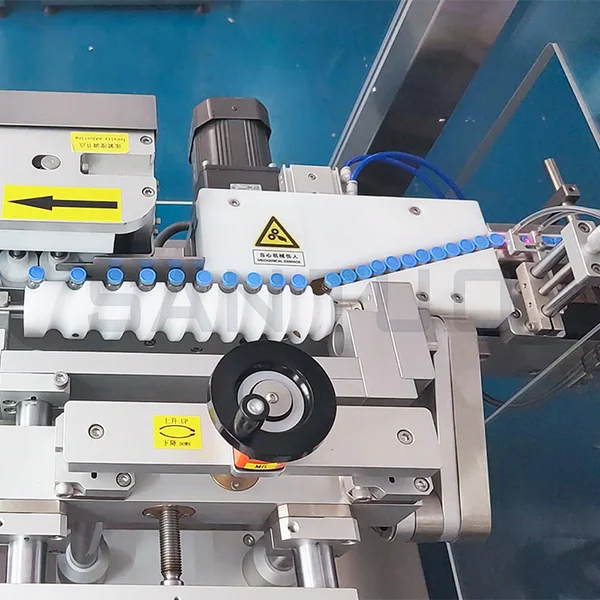

A vial labeling machine with turntable is an automated labeling system specifically engineered to handle small cylindrical containers with precision and speed. The key feature of this system is its bottle separation and positioning mechanism. Bottles are separated using a screw system and are guided by vertical rollers connected to the main star wheel. This, in combination with a rolling belt, forms a three-point positioning system that ensures each bottle is held firmly and accurately in place.

By integrating PLC control of the main star wheel with a servo high-speed labeling head, the machine achieves both precise and high-speed labeling, making it ideal for pharmaceutical manufacturing environments that demand strict accuracy and regulatory compliance.

Key Features and Advantages

The vial labeling machine with turntable offers a range of features that make it a versatile and reliable solution for small bottle labeling:

Three-Point Positioning System – Ensures stable and accurate bottle placement for consistent label alignment.

High-Speed Labeling – Servo-controlled labeling head achieves rapid labeling without compromising accuracy.

PLC Integration – Facilitates automated control, monitoring, and adjustments for seamless operation.

Versatile Container Handling – Suitable for vials, ampoules, oral liquid bottles, and other small pharmaceutical containers.

Minimal Downtime – Easy-to-adjust mechanisms reduce changeover time between different bottle sizes.

User-Friendly Operation – Intuitive interface allows operators to control speed, position, and label application efficiently.

These advantages allow manufacturers to maintain high throughput while ensuring consistent labeling quality, meeting the rigorous standards of pharmaceutical production.

Applications in Pharmaceutical and Industrial Industries

The versatility of the vial labeling machine with turntable extends to multiple industries where precise labeling is essential:

Pharmaceutical Industry – Labels medication vials, oral liquids, and ampoules with high accuracy, ensuring compliance with regulatory standards.

Cosmetic Industry – Suitable for small cosmetic bottles, serums, and essential oils, maintaining consistent label placement.

Laboratory and Research – Supports labeling of test tubes, sample vials, and other containers in laboratory settings.

Food and Beverage – Efficiently labels small liquid containers, such as flavor extracts and liquid supplements.

Chemical Industry – Ensures safe and accurate labeling of small chemical bottles and reagents.

The system’s adaptability to different container types and sizes makes it a valuable asset across multiple sectors that require both precision and high-speed labeling.

Operational Efficiency and Productivity

By combining mechanical precision with advanced control technology, the vial labeling machine with turntable offers significant operational benefits:

Increased Production Efficiency – High-speed labeling reduces bottlenecks on the production line.

Consistent Labeling Accuracy – Three-point positioning system prevents misalignment and reduces product waste.

Scalable Performance – Easily handles varying production volumes without compromising labeling quality.

Regulatory Compliance – Accurate labeling ensures traceability and adherence to pharmaceutical standards.

Cost Savings – Reduces labor requirements and minimizes downtime, delivering a high return on investment.

These operational benefits ensure that production lines remain competitive while maintaining the highest quality standards.

Conclusion

The vial labeling machine with turntable is a high-precision, high-speed solution for labeling small pharmaceutical containers, including vials, ampoules, and oral liquid bottles. By combining a three-point positioning system with PLC and servo control, it ensures stable, accurate, and efficient labeling across diverse industrial applications.

From pharmaceutical production to cosmetics, laboratories, and chemical packaging, this machine enhances operational efficiency, reduces labor costs, and ensures compliance with stringent quality standards. For manufacturers seeking precision, speed, and reliability in small bottle labeling, the vial labeling machine with turntable is an indispensable investment.

https://www.santuomachine.com/versatile-uses-of-vial-labeling-machine-with-turntable.html